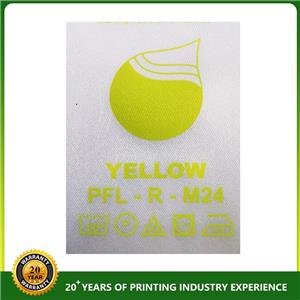

flexo label ink

-

Flexo Fabric Rotary Label Printing ink For Textile Cloth Ribbons

How to use this flexo label ink : Please mix the ink thoroughly before use; Please use special diluent, adjust the dilution within 3-10%; In order to improve the adhesion, 3-10% of special hardener can be added. After adding, it needs to be fully stirred. The ink can be used for 4 hours after being mixed. So please be careful not to blend too much at one time), you need to fully dry after printing; The conventional drying methods are: hot air blowing and drying. After the printed trademark tape is fixed in a constant temperature oven, it can achieve extremely high color fastness. Ribbons and woven tapes are dried in a 100 degree oven for 4 hours (120 degrees and 2 hours), nylon, cotton tape, and polyester are dried in an 80-90 degree oven for 4-8 hours. The effect of dry cleaning. The drying, adhesion and ink film characteristics of the ink are related to the time of the drying temperature.

Email Details