Requirements of offset printing on rubber blanket and its installation skills

Three characteristics of offset printing

1. Offset printing uses the middle Cylinder of elastomer blanket to form a unique rolling mode of indirect printing.

2. Using the selective adsorption law of different properties of solid surface, through technical treatment, the solid surface can meet the needs of lithography.

3. Using the natural law of immiscibility of oil and water, the offset printing process not only transfers ink, but also water.

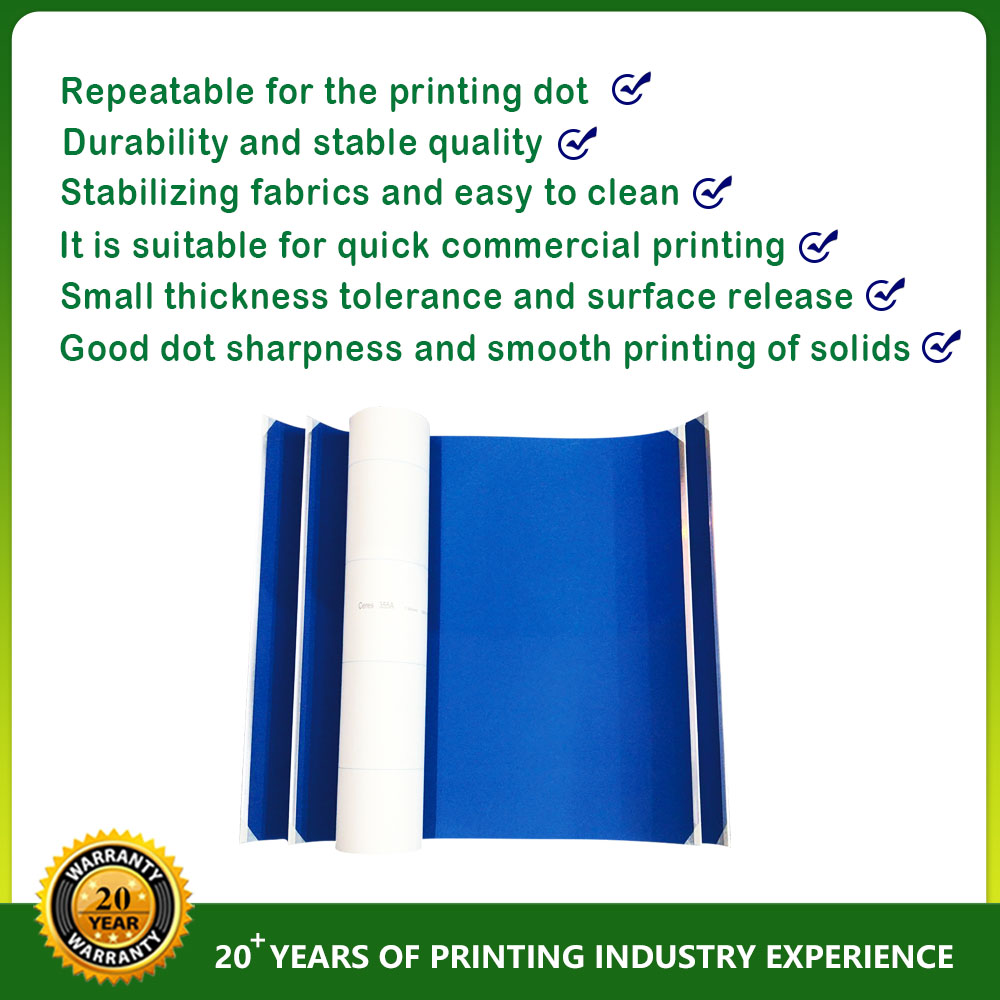

Rubber Blanket plays an important role in transmitting printed pictures and texts. The quality of blanket is directly related to the quality of transferred pictures and texts.

What are the requirements of offset printing for blanket quality

In the process of offset printing, the function of blanket is to transfer the picture and text on the printing plate to the paper completely and clearly. In order to achieve the perfect transfer of picture and text, the blanket must have the following characteristics:

1. The thickness of the blanket should be even. The uniform thickness will make the printing pressure evenly distributed, and the ink color will be more even when printed, and the size of the image and text is not easy to change during the process of image and text transfer.

2. Has good flexibility.

3. The blanket has a smaller elongation.

4. Good ink absorption and transfer performance. It can ensure that the ink color is even and the writing is clear during the printing process.

5. The rubber cloth has good oil resistance, abrasion resistance, heat resistance and anti-aging properties. It has all the above properties and can extend its service life.

6. It has the performance of acid resistance, alkali resistance and corrosion prevention. Because the blanket is penetrated by gasoline, kerosene, and engine oil during the printing process, it is subjected to pressure and relative friction between the roller and the roller, and is periodically stretched, squeezed and deformed. The blanket will become sticky and deformed due to sulfur loss. The lack of good elasticity affects the transfer quality. In this case, the old blanket must be replaced.

Problems to be paid attention to when installing rubber blanket

1. When installing the rubber blanket, pay special attention to no wrinkling of the gasket.

2. When tightening the blanket, both sides of the trailing end and the bite should be carried out at the same time, not on one side.

3. The new blanket has good elasticity and good extensibility. Tension the blanket gradually. After the first time of tension, wait for the offset press to press for 3 ~ 5min, and then tension it again. In this way, the requirements of tension can be achieved by repeated 2 ~ 3 times.

7. The underpacking paper in the rubber cloth lining should be shorter than that in the rubber cloth to avoid water penetration.

- Security Ink

- Security Paper

- UV Invisible Ink

- Watermark Ink

- Optical Variable Ink

- Magnetic Ink

- Water Sensitive Ink

- Photochromic Ink

- Temperature Sensitive Ink

- Infrared Ink

- UV Fluorescent Ink

- Glow In The Dark Ink

- Glass Ink

- Mirror Ink

- Conductive Ink

- Scratch Off Ink

- Laser Ink

- security printing auxiliary materials

- Printing Chemical

- Plate Cleaner

- Spray Powder

- Hot Melt Adhesive

- Jelly Glue

- Gun Solution

- Fountain Solution

- Quick Drier Plus

- Printing Materials

- Rubber Blanket

- Printing Plate

- Dampening Sleeves

- Cutting Stick

- Creasing Matrix

- Double Wire

- Ink Duct Foil

- Underpacking Paper

- Underpacking foil

- Sponge

- Pantone Color Chart

- Ink Knife