two-piece can

concept

Two piece cans were invented in the middle of the 20th century. The whole packaging can is composed of two parts, namely, the can body and the can cover, so it is called two-piece can. It belongs to a kind of metal can.

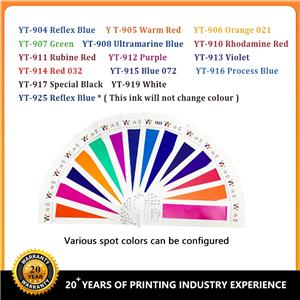

two piece ink printing ink supplier : www.enyyink.com

principle

The can body of the two-piece can is a metal sheet, which is stretched and deformed by a punch through a stretch forming die, so that the can body at the bottom of the can is connected as a whole.

classification

There are many kinds of tank bodies of the two-piece tank: according to the height of the tank body, it can be divided into shallow flushing tank and deep flushing tank; Divided into aluminum cans and iron cans according to can making materials; According to the manufacturing technology, it can be divided into thinning drawing cans and deep drawing cans.

Advantages and disadvantages

Two piece cans have the following advantages over three piece cans:

① Good sealing. The tank body is formed directly by the punching process, without leakage, and the leakage detection process can be avoided

② Ensure product quality. The two-piece cans do not need to be sealed by welding, so as to avoid the lead pollution of the solder cans, and are resistant to high temperature sterilization, which can ensure the hygiene of the products.

③ Beautiful and generous. The tank body has no seams, and the shape is beautiful, and the tank body can be continuously decorated and printed, with good effect.

④ High production efficiency. The two-piece can has only two parts, and the manufacturing process of the can body is simple, which is very good for simplifying the process and improving the production capacity

⑤ Save raw materials. The can body of the two-piece can is stretched and deformed during forming, and the wall thickness is thinner than that of the three-piece can; In addition, the can body of the two-piece can is formed as a whole, without longitudinal seam of the can body and seam with the bottom of the can, which also saves materials. However, two-piece cans have higher requirements on material performance, can making technology, can making equipment, etc., and there are fewer types of filling materials.

application

At present, the metal cans used for packaging are mainly aluminum two-piece cans. The aluminum two-piece can is made of aluminum alloy thin plate, and the thinning and stretching process is used in the manufacturing process, so the thickness of the tank wall is significantly thinner than that of the tank bottom. When used in beer packaging, strong internal pressure will make up for the rigidity of thin can wall. However, the high gas resistance, shading and sealing of metal cans will keep the quality of beer in the cans stable. In addition, it is the existence of these metal features that enable metal cans to be filled at a high speed even if the time-consuming filling method of isobaric filling is adopted.

Entry Label:

Metal can two piece can packaging